Tenax PW is a carbon fiber used in airplanes.

Its durability and robustness, which are heightened for airplane safety, not only withstand powerful playing, but are also perfect for hard hitters and power hitters, as power is directly transmitted to the ball.

-

Highly shock-proof

Perfect for hard hitters and power hitters

-

High-strength, high-elasticity resin

Hard, strong, and resilient to breakage

-

Used in airplanes

Track record of safety and high performance

Products using Tenax PW

Product features

01Highly shock-proof

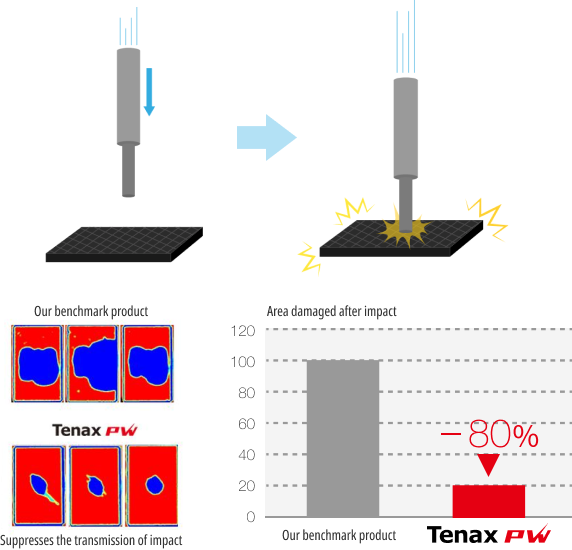

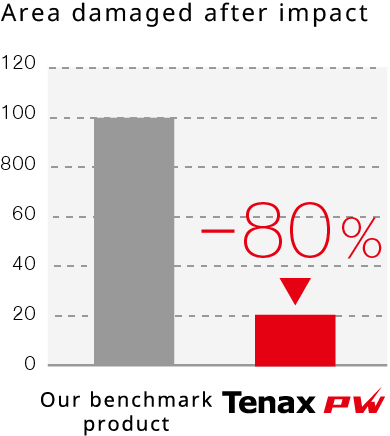

Excellent toughness, minimizing the damaged area after impact by 80%.

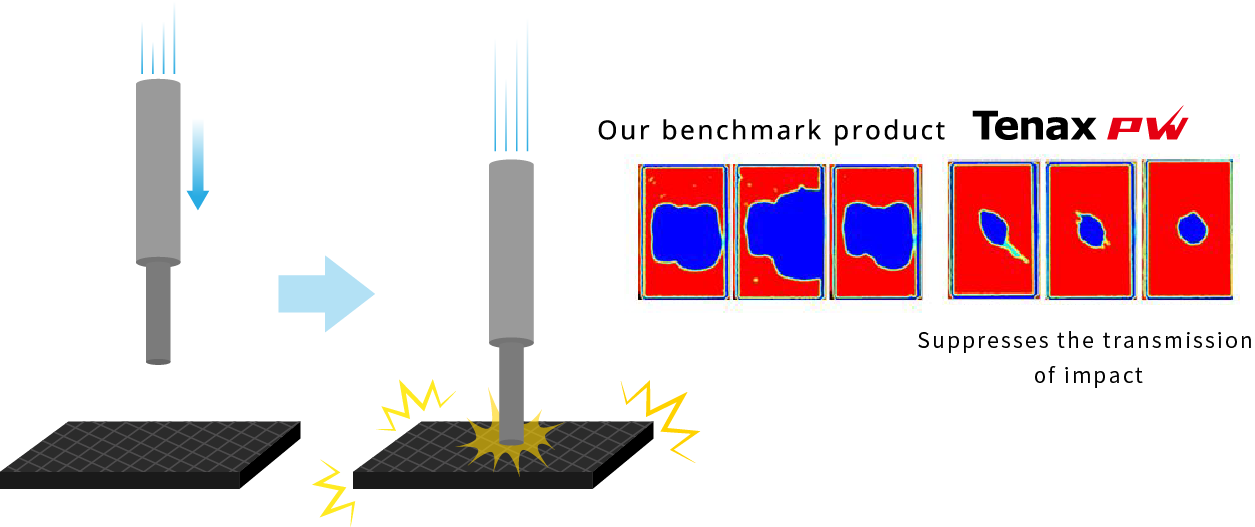

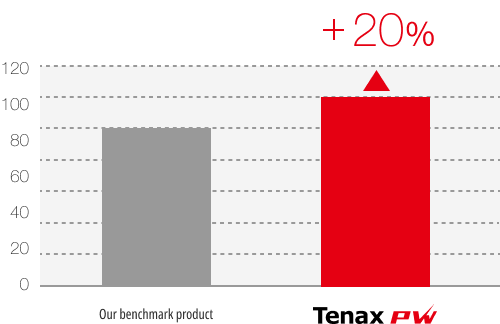

■Compressive strength test after falling weight impact

A weight is dropped onto a postcard-sized CFRP* test piece to evaluate what area of the test piece was damaged.

A compressive strength test is further performed on the test piece after it sustained damage from the fallen weight.

The result indicates the CFRP’s toughness (tenacity).

Generally speaking, the higher the modulus of elasticity (= hard), the less tough (= fragile) the material is.

However, even though Tenax PW demonstrates a higher modulus of elasticity than our benchmark product, its area damaged after the impact of the falling weight is 80% smaller. This is proof of excellent tenacity of Tenax PW.

The coexistence of the high modulus of elasticity and tenacity is the most outstanding characteristic of Tenax PW, a material used in airplanes.

*CFRP: Carbon fiber reinforced plastic (carbon fiber composite material)

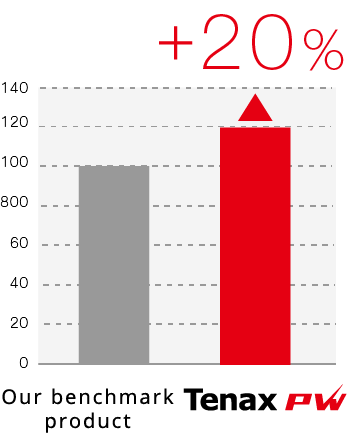

02Highly elastic

Features resins of the level used for airplanes, even for forces in the direction in which carbon fiber does not work, demonstrating excellent rigidity (= resistance to deformation).

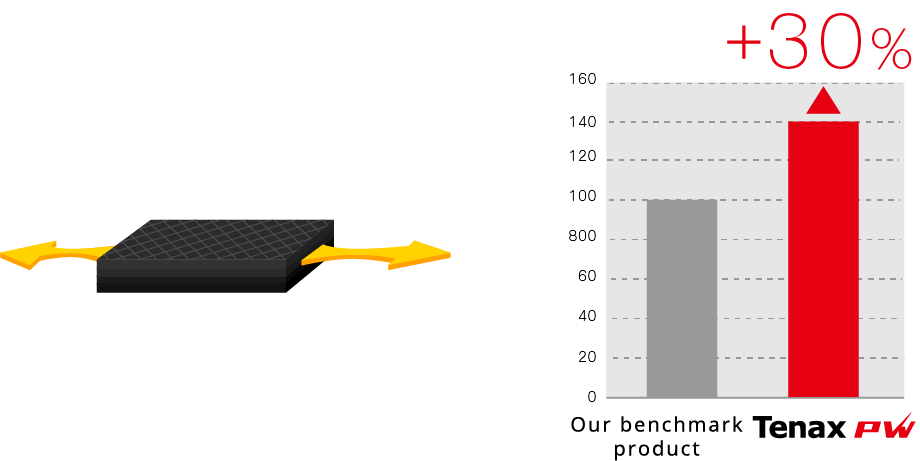

■Modulus of resin elasticity

Indicates the modulus of elasticity (hardness) of the matrix resin that reinforces carbon fiber.

CFRP* with carbon fiber as a reinforcer demonstrates excellent tensile strength.

However, since carbon fiber itself is a fine fiber, its compressive strength will drop against tensile strength.

That is why Tenax PW features a resin with a higher modulus of elasticity (a harder resin) than that of standard resins to support carbon fiber, to improve CFRP’s compressive strength.

In short, Tenax PW demonstrates excellent durability even for a compressive load that is usually hard for CFRP to withstand.

*CFRP: Carbon fiber reinforced plastic (carbon fiber compound material)

03High durability

Demonstrates excellent durability against forces with ±45 orientation.

Improved in-plane shear strength, which is an indicator of durability

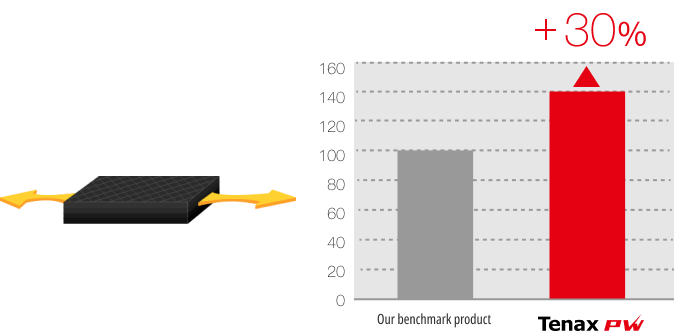

■In-plane shear strength

In-plane shear strength indicates the strength and durability of the reinforcement resin around the carbon fiber.

It shows the strength (resistance) of the CFRP* test piece with the carbon fiber at ±45 orientation when it is pulled from the sides at a 0-degree orientation.

Please access this website to send us questions about our products,

and inquiries about the use of our brand logos,

promotional movies, and other tools.