History and evolution of the bat

The origin of softball lies in indoor baseball, a sport played in the U.S. in the latter half of the 19th century. From that time to today, various rules have been established, and the equipments have continued to evolve.

As part of that evolutionary process, materials of bat have changed from wood to metal, and then to carbon for lighter weight and better flight. Players emphasize bat lightness because it’s directly linked with their initial motion. With a top-level pitcher, the ball speed perceived by the hitter is said to exceed 160 km/hr, and the batter swings too late. This is because the distance between the pitcher and the hitter is shorter than in baseball.

The flight is another characteristic emphasized by players.

However, restrictions came into effect in Japan in 2016. Use of bats whose flight is too great was prohibited by restrictions on the coefficient of restitution. Softball is a game played on a compact field with a sense of speed. If a powerfully batted ball strikes a player, it may cause serious injury. The restrictions aimed to prevent that.

The "hard hit" feeling is the key

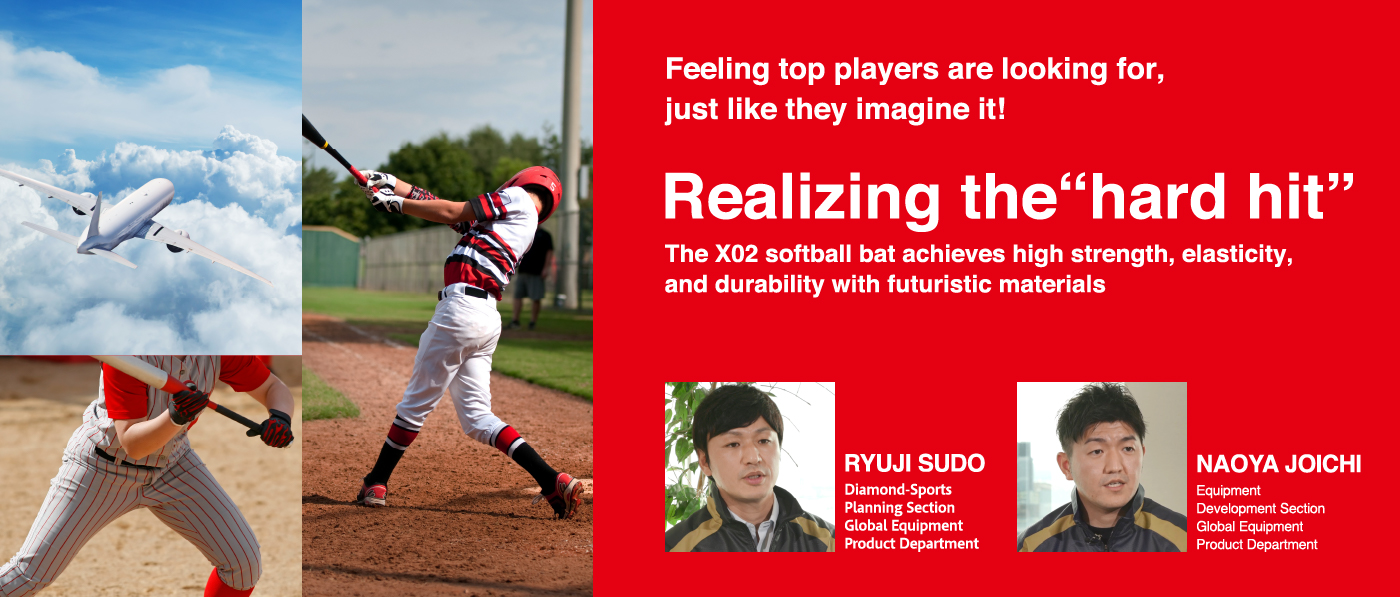

Naoya Joichi belongs to the Equipment Development Section at MIZUNO, which supported the Japan women's national team whose achievements were so memorable at the Olympics. He said: “We used to focus on how to create a bat with the long flight, but due to the new restrictions, the condition of restitution is the same for all producers. Listening to the views of players, we found they were looking for the feeling of a hard hit. But achieving that with conventional materials was difficult.”

At this point, the “Tenax” carbon fiber from Teijin came to the fore. Carbon fiber is a material drawing attention because it has strength ten times that of steel, with only one forth the weight. MIZUNO thought they could achieve the desired hard hit feeling by choosing optimal characteristics for the carbon fiber and resin as well, and then combining the two. However, it wasn’t that easy. Ryuji Sudo of MIZUNO’s

Planning and Production Section opens up about a tough failure he could not speak of until now.

"We brought the first prototype to a practice by the Japan team. When they tried hitting with it, there was a gap between the players' desires and the bat performance. It wasn't a satisfactory result. We were very disappointed."

To clarify why there was this gap, they worked together with the engineers of Teijin. In the material selection, they combined high-strength carbon materials with special resins to meet player needs, and the best molding condition was found through repeated trial-and-error improvement, while adjusting factors such as the temperature, pressure, time, and other processing conditions during the molding.Finally, a durable product with a good hit feeling was perfected, just like the player's envisioned. This was the X02 bat using Tenax PW. Joichi and Sudo are proud of realizing an ideal bat with high strength and elasticity, as well as outstanding durability.

Commercializing equipment that meets

player needs while striving to achieve SDGs

Commercializing equipment that meets

player needs while striving

to achieve SDGs

In the past, MIZUNO has commercialized equipment suited to the needs of players both inside and outside Japan. For example, there is the one-piece type with integrated grip and head for Japanese players who hit with technique. For American players who hit with power, there is the two-piece type which reduces numbness when the ball is hit near the bat handle. In adjusting bat weight balance,MIZUNO has capitalized on its technical capabilities—providing a near-side center of gravity for players who emphasize subtle bat control, and tip-side center of gravity for players who have power and use the centrifugal force of the bat.

Sudo remembers an interesting comment by Eri Yamada, a player on the Japanese team currently using the X02. "In the past, the main objective of batters was a solid, powerful swing in order to not be defeated by high rise balls. However, today there are a variety of pitches, such as the slower ball (i.e. the changeup) and the curve, and hitting must be done by reliably adjusting the bat when the ball has been controlled low, so a hybrid swing (batting) technique is needed."

Eri Yamada has been active for many years as a player on the Japanese national team, and she prefers the hard hit feeling. She has selected the X02, clearly demonstrating that the X02 is a bat enabling hybrid batting, with the hit feeling and weight balance Yamada is looking for.

Aside from zeroing in on player needs, and developing/commercializing products with superior functionality, what will be necessary going forward is SDGs (Sustainable Development Goals). Joichi emphasizes that "Thus far, we've concentrated on improving bat performance, but in future development we will have to consider how we can contribute to achieving a sustainable society through sporting goods." MIZUNO's stance agrees with the sustainability policy of their material supplier Teijin. The tag team of MIZUNO and Teijin will surely advance toward the dream of "recyclable bats."